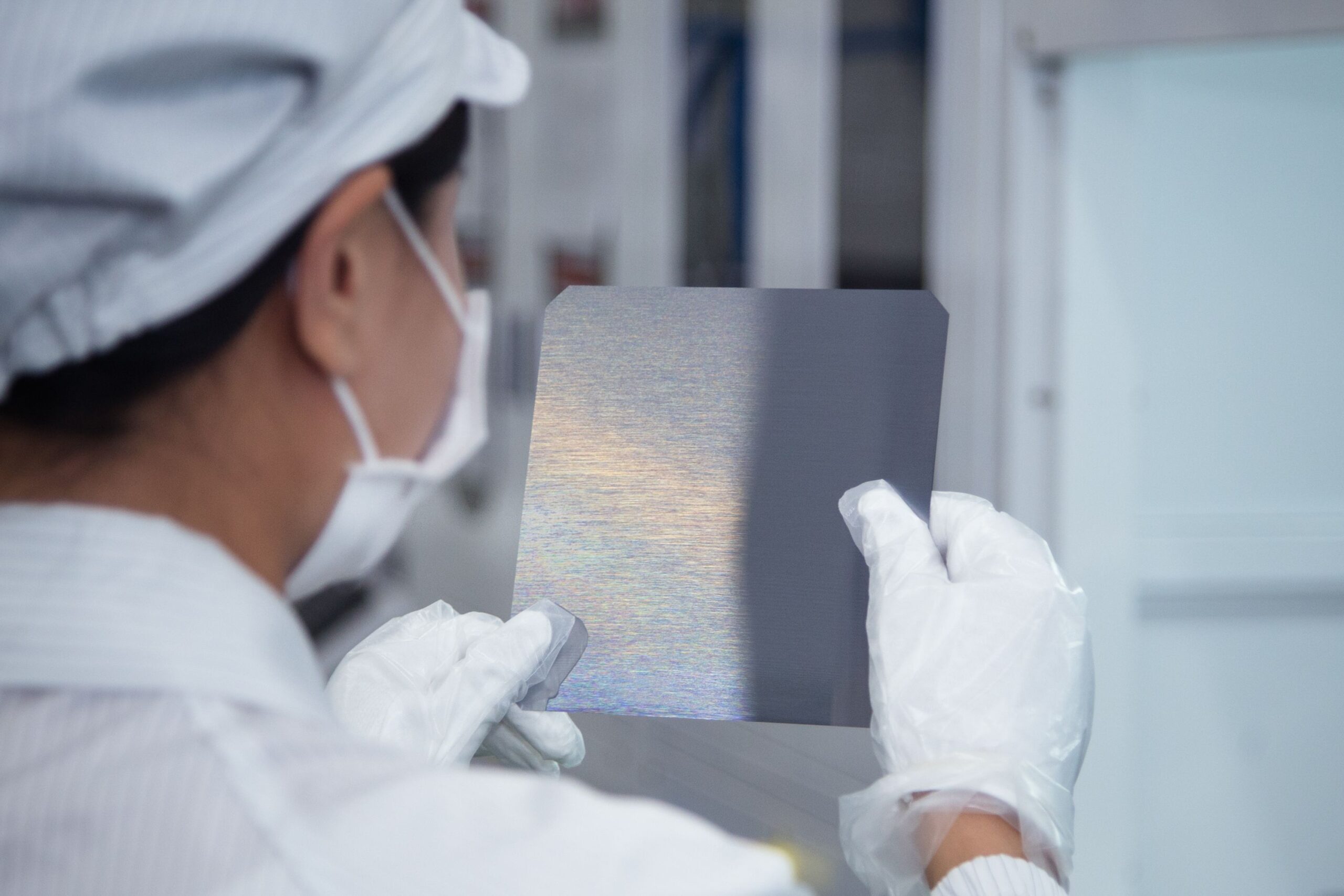

The production process for monocrystalline silicon wafer includes crystal pulling, square cutting, slicing.cleaning and sorting. Through continuous improvement of the cutting process and final inspection capability.the production capacity and silicon wafer vield rate have been continuously improved to meet customerdemands for silicon wafer quality and output.

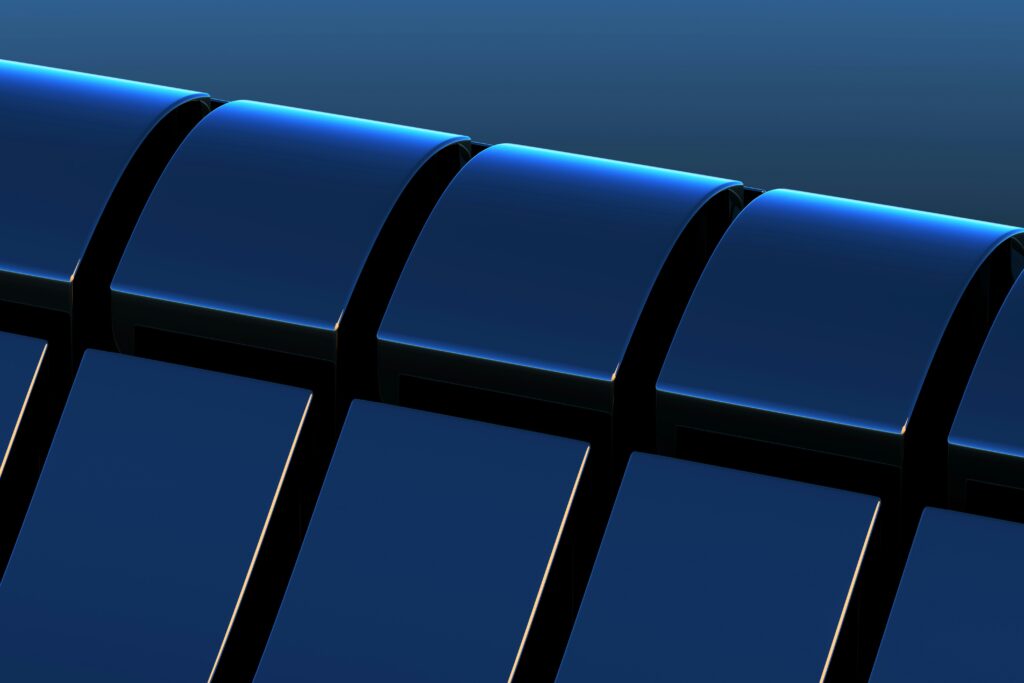

Through advanced manufacturing methods and next-generation materials, our Tier 1 partners have reduced production costs while increasing module efficiency and reliability. Automated control systems and continuous process innovation ensure that every solar panel delivered by GRW Solar combines performance, durability, and affordability — making clean energy more accessible across Latin America.

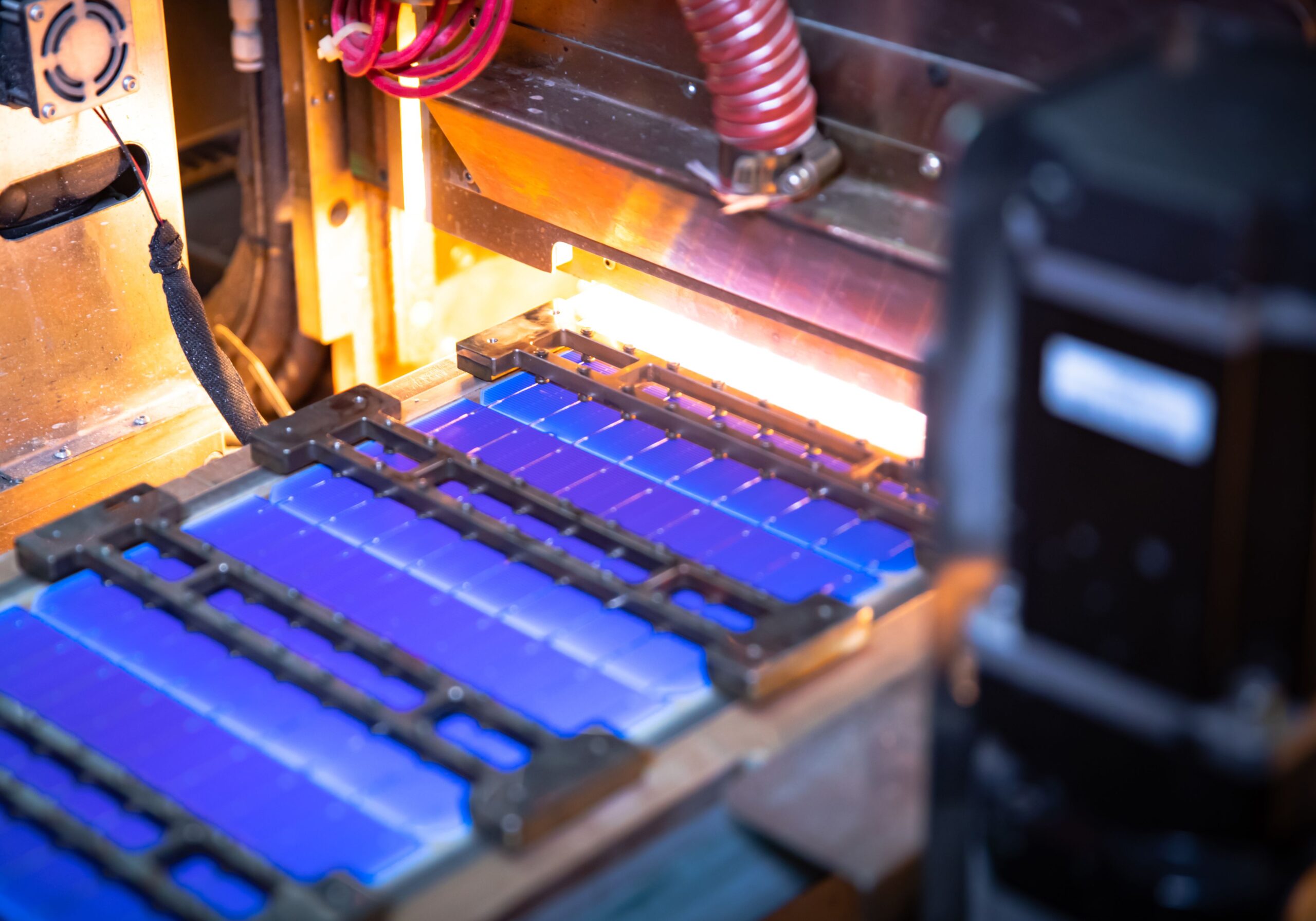

Through the improvement of the quality of monocrystalline silicon wafers and the optimization of the cell-side process, monocrystalline has basically solved the initial attenuation problem and disclosed this technology to the entire industry.

Intelligent manufacturing can improve the effective production capacity, greatly reducing the number of workers and improving the consistency of the crystal growth process. Smart automation tools are used to control the single crystal furnace, reducing human intervention in the crystal growth process.

The costs of non-silicon raw and auxiliary materials used in crystal pulling account for about 25% of the total cost. Prolonging the service life of non-silicon raw and auxiliary materials is an important way to reduce the crystal-pulling cost. Examples include carbon-carbon composite materials and crucible coating technology.

Advanced wafer slicing techniques can greatly improve the yield per kilogram of monocrystalline and the slicing capacity, contributing greatly to the value of the product and supporting ongoing cost reductions of monocrystalline and polycrystalline silicon wafers.

GRW Solar partners with Tier 1 manufacturers who invest heavily in R&D, focusing on innovation, cost reduction, and efficiency improvements in solar technology. By turning cutting-edge research into scalable products, our partners ensure that every module delivered to Latin America reflects the latest advancements in clean energy. These manufacturers collaborate with world-renowned institutions and research centers, ensuring continuous progress and maintaining leadership in the global solar industry.

From residential rooftops to utility-scale plants, GRW Solar delivers Tier 1 modules with certified quality and DDP delivery across Latin America.